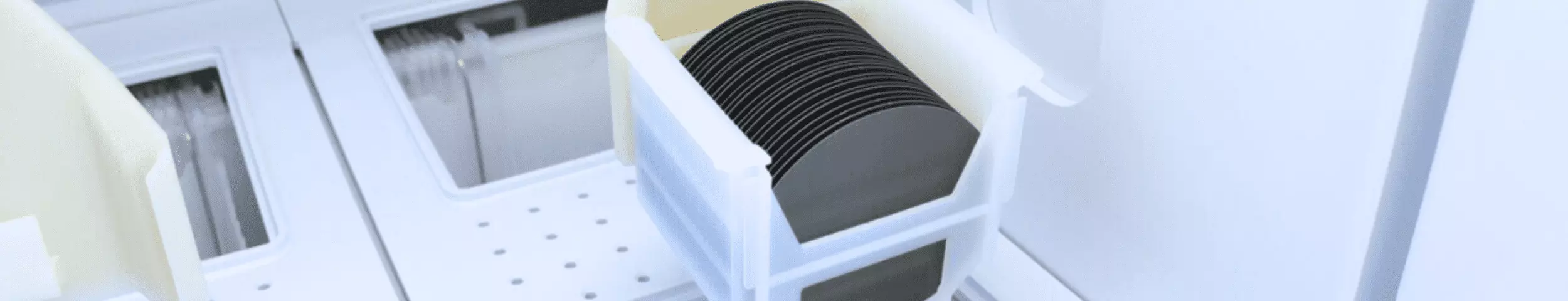

Advancer Gemini Wet Bench

Dual-process, Single-step Immersion Wet Bench

The Advancer Gemini Wet Bench is a dual-process, dual-robot wet processing system. It is one of the most cost-effective platforms available.

The Advancer Gemini dual processing takes advantage of sharing not only the IDX Flexware Control system but the required facilities as well.While doubling the processing capacity within a reduced overall footprint, the Advancer Gemini provides twice the attractive features for a relatively low cost. The Advancer Gemini wet bench features all the capabilities of the Advancer Classic wet bench while producing twice the throughput per square foot. The Advancer Gemini wet bench can also be configured for sequential process steps within a single module.

Features and Benefits:

- Dual-Step Processing and Rinse Design

- Single and Dual Cassette Capability

- 50mm up to 200mm Wafer Sizes

- 6″ and 8″ Processing with no Changes

- IDX Flexware Process Control Software

- Intuitive HMI Touchscreen

- Two Accessible Side-mounted Robots

- SECS/GEM Compliant

- Factory Host

- UL Listed 508A Electrical

- Dual Process tanks per Module

- Shared Facilities

- Shared Electronics

- Single Control I/O System

- Reduced Footprint

- Improved Process Control

- Reduced DI Water Usage

- Reduced Chemistry Usage

- Extended Tank Life

- Low Cost of Ownership

- Maintenance Friendly

- Easy Installation

Contact our Experts

We are happy to help our customers find efficient and process-optimized solutions for their wet processing applications.