Spray Acid Tool

Features and Benefits:

- Manual Load

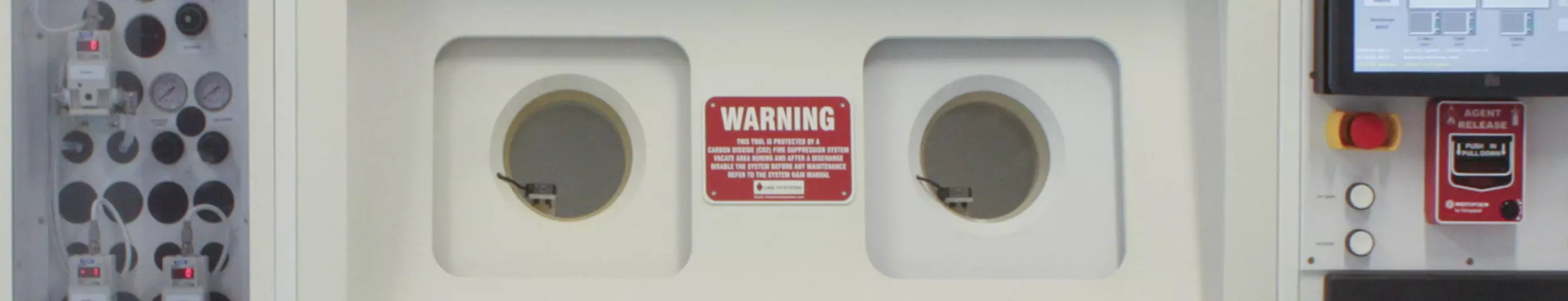

- Single and Dual Process Chambers

- Compacted Footprint

- Three cabinet Sizes

- 24 in, 76 in and 92 inches wide

- 25 wafer load 50mm to 200mm low pro

- Typical Throughputs: Single Chamber 75-100 wph, Dual Chamber 150-200 wph

- Enclosed controlled environment

- Dry to Dry operation

- 25 wafer chamber

- 2 and 4 tank configurations

- On board chemical mixing with metering pumps and level sensors

- 23 liter tank with full level set at 16 Liters

- On-axis horizontal wet-processing design keeps wafers parallel to the flow

- Uniform boundary layer coverage across load

- Options: End Point Detection and Chemical Concertration Monitoring

- Increased Bath Life

- Software programmed time based over-etch allows for consistent run to run processing

- EPD overcomes the challenges of visually inspecting the wafer surface during process as the metal etch occurs.

- Optimized Process

- Recipe step advance is determined by when the etch is complete, not by a pre-set amount of time resulting in consistent processing.

- Higher throughput results from faster etch process steps.

- Clamshell Carriers used to see front wafer to detect when etch is complete

Contact our Experts

We are happy to help our customers find efficient and process-optimized solutions for their wet processing applications.