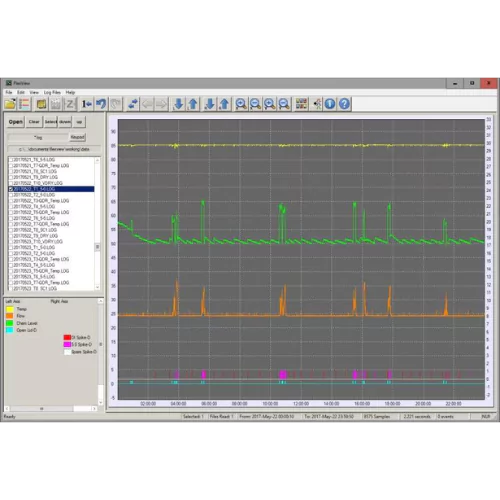

FlexView

Advanced Process Monitoring Software

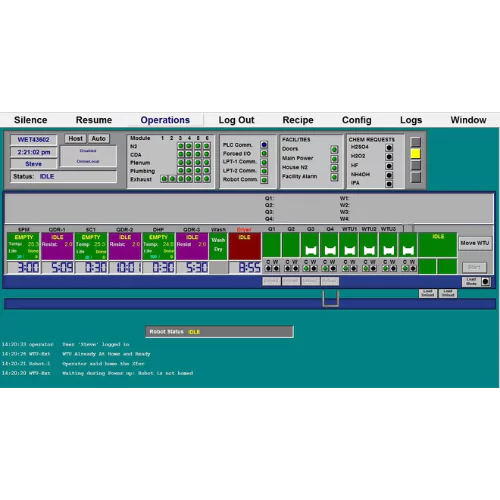

RENA’s Flexview Advanced Process Monitoring Software enables equipment and process engineers to review the processing conditions of a specific lot ID at a glance.

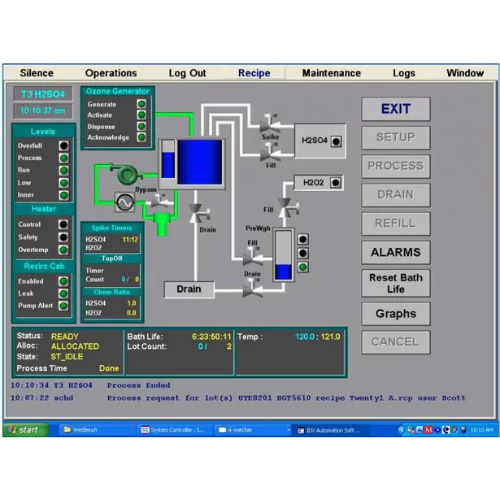

FlexView software does this by providing a graphic representation of all existing monitored conditions & tolerances, then storing that data in a file that is specific to the Lot ID that was being processed at that time. In the event of a yield loss on a particular lot, the process engineer can quickly identify if the wet station processed that lot within the required specifications. In this way, the system can be much more easily eliminated as a possible cause of the yield loss even. FlexView eliminates the need to interpret large amounts of data in the data log. This creates the opportunity for greater system optimization and process transparency while improving the overall operator experience.

Features and Benefits:

- All relevant, recorded process data is stored by LOT ID

- At-a-glance post-process review of all critical parameters

- Advanced Process Control package

- 64 Data Point Analysis*

- Split-screen Viewing Configuration

- Configurable Charts & Views

- Macro & Micro Viewing

- Overlay Simultaneous Data & Events

- Compatible with all Windows-based PCs*

- Easily Tailored to Customer Specifications

- Easily Tailored to Customer Specifications

- Intuitive Graphical Interface

- Reduced Production Costs

- Reduced Chemical Consumption

- Reduced Chemical Waste

- Field-proven Reliability

- Award-winning, Worldwide Support

*The actual total amount of data points is determined by the integrated hardware and their available parameters. FlexView can track and chart a maximum of 64 unique data points.

Contact our Experts

We are happy to help our customers find efficient and process-optimized solutions for their wet processing applications.