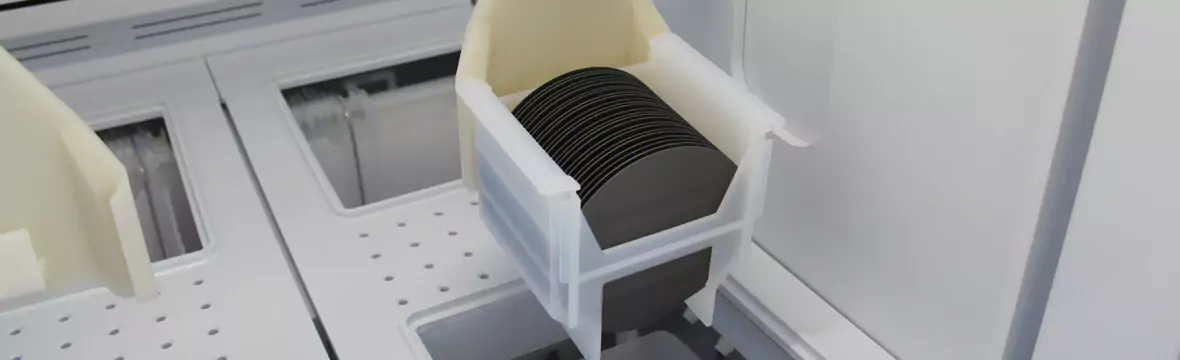

Advancer Classic Wet Bench

Single-step, Semi-auto Wet Processing System

The Advancer Classic Wet Processing System is a robust, field-proven single-step solution for today’s popular applications. The Advancer platform, by nature, is highly configurable, and extremely maintenance-friendly.

As with all RENA systems, is controlled and monitored by IDX Flexware. IDX introduces advanced features and capabilities only found on RENA wet processing systems.

Features and Benefits:

- Dry-to-dry Capability

- Single-Step Process and Rinse Design

- Single or Dual Cassette Capability

- 50mm to 200mm Wafer Sizes

- 6″ and 8″ Processing with no Changes

- IDX Flexware Process Control Software

- Intuitive HMI Touchscreen

- Highly Serviceable Side-mounted Robot

- SECS/GEM Compliant

- Factory Host

- UL Listed 508A Electrical

- Improved Process Control

- Reduced DI Water Usage

- Reduced Chemistry Usage

- Extended Tank Life

- Low Cost of Ownership

- Multiple Models Available

- Reduced Footprint

- Maintenance Friendly

- Easy Installation

Contact our Experts

We are happy to help our customers find efficient and process-optimized solutions for their wet processing applications.