VaporDry

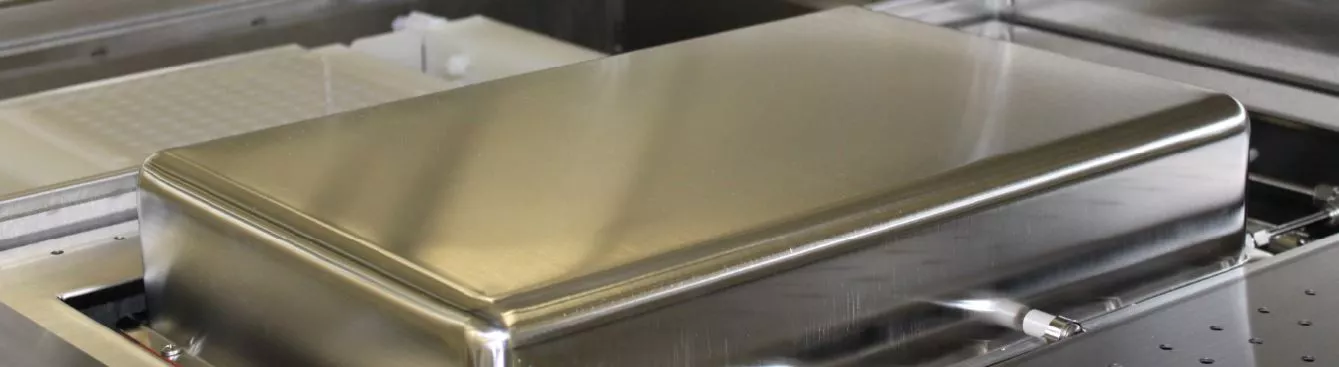

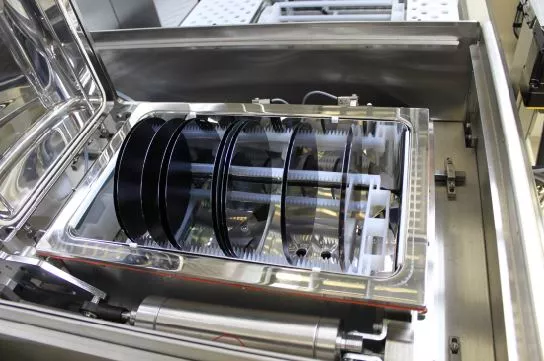

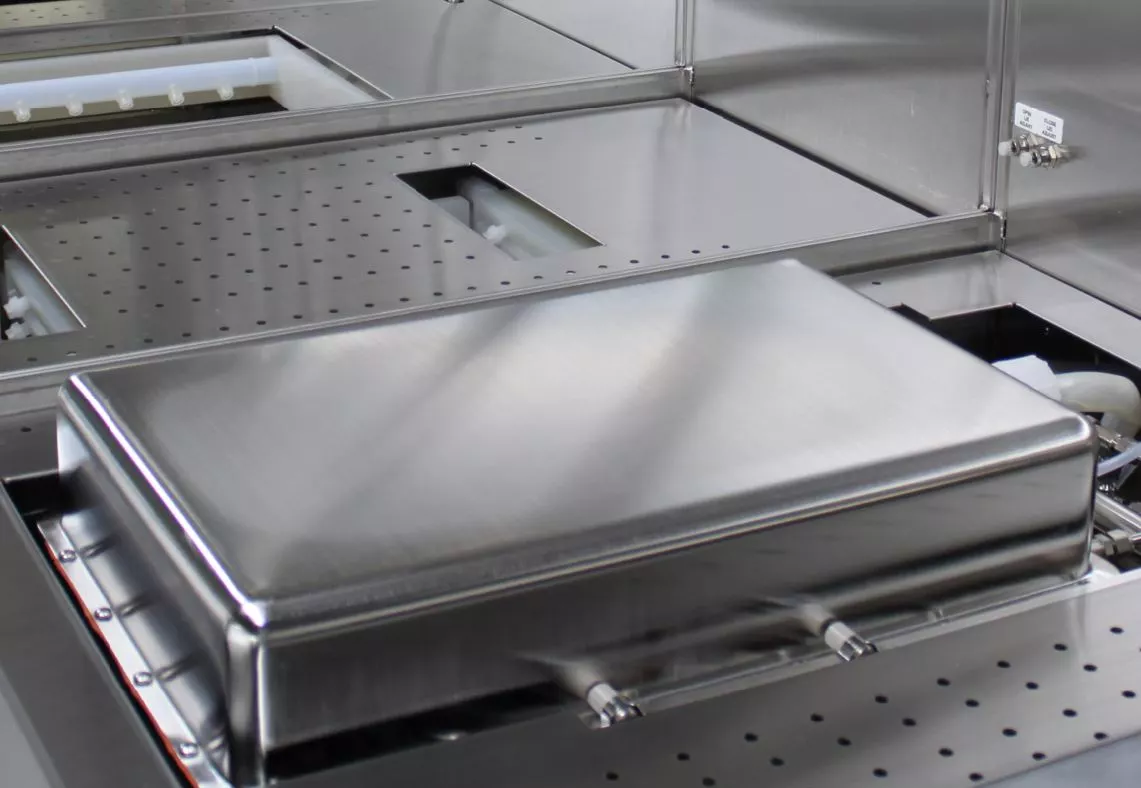

RENA’s VaporDry, Integrated IPA Drying Process displaces water from high aspect ratio features and TSV, effectively drying the most complex surfaces.The entire process is monitored and controlled by RENA’s proprietary IDX Process Control software. VaporDry is the ideal solution for 3D Compound Semiconductor and TSV Applications.

Features and Benefits:

- 85% Reduction in IPA Usage vs Boiling Sump Vapor Dryers

- Lower IPA usage compared to boiling sump vapor dryers

- 200ml/cycle

- Semiconductor, Dryer, IPA

- IDX Flexware Process Control Software

- Completely dry “High Aspect Ratio” structures and TSV > 750um deep

- Particle performance < 20 at 0.12μm

- All EP stainless steel construction

- Low Complexity

- Lower IPA Usage

- Efficient & Clean

- Robust, reliable, field-proven performance

- Small Footprint

- Extremely effective for Teflon cassettes

- Ideal for drying multiple wafer sizes

Contact our Experts

We are happy to help our customers find efficient and process-optimized solutions for their wet processing applications.