TruEtch WAFER ETCH SOLUTION

Critical Etch solutions with TruEtch Processing Technology

(Patent Protected in USA, Europe, and Asia Patent No. 9,562,291)

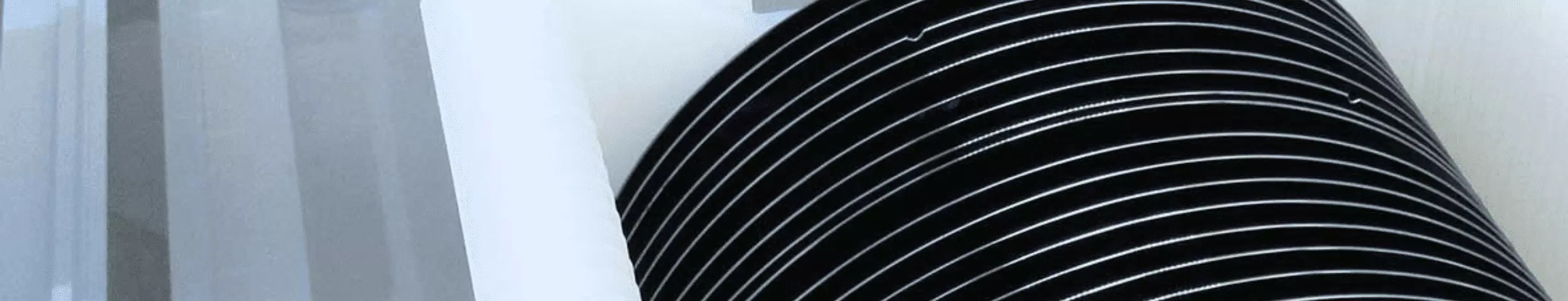

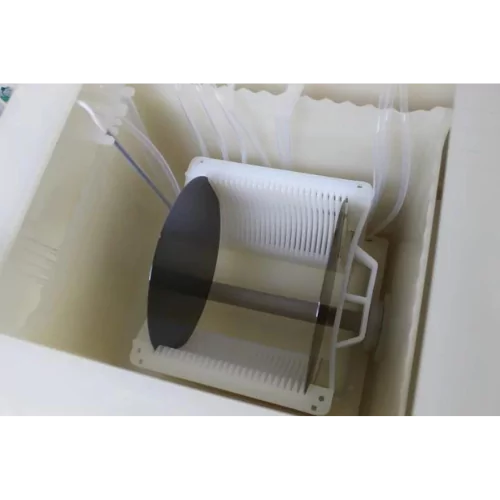

Through superior Wet bench immersion systems designed to utilize integrated wafer rotation and precise micro bubble agitation for superior wetting and uniform etching of noble metal layer patterns for Si, Si02, and III-V materials. With TruEtch RENA offers critical etching solutions with advanced hardware, complete process understanding & precise software execution for pattern metal etching.

Features and Benefits:

- Greater Stability

- Field Proven Reliability

- Higher Uptime

- Reduction in Chemical Consumption

- Reduction in Waste Treatment

- Less Arsenic Waste Generated

- Lower Exhaust Requirements

- Smaller Footprint

- Lower Cost of Ownership

- Advanced Software Capabilities

- Award-Winning Service and Support

Consistent Etch Performance

- Via a Closed-loop Process Control

- Higher throughput than Spray Tools

- Lower Chemical Usage

- Advanced Tank Designs

- Advanced Flow Control

- Integrated Wafer Rotation

Etch Stability Concentration Control

- Accurate Concentration Control

- Accurate Chemical & DI Spiking

- Consumption/Evaporation Compensation

Increased Reliability

- MTBF 1500 hrs

- Avg MTTR 1 hr

- Higher uptime 95%

- Reduced scrap

- No complex wafer handling

Patent No. 9,562,291

Contact our Experts

We are happy to help our customers find efficient and process-optimized solutions for their wet processing applications.