Genesis Stand-Alone Marangoni Dryer

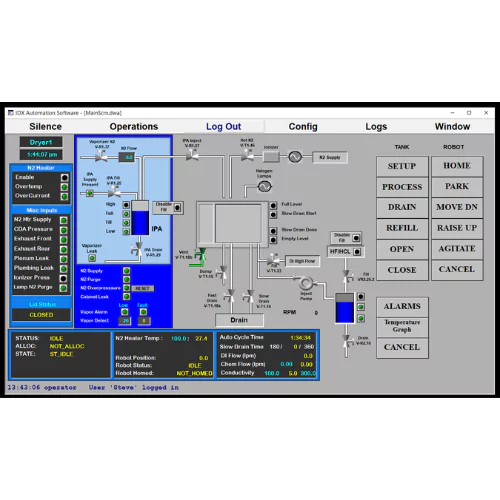

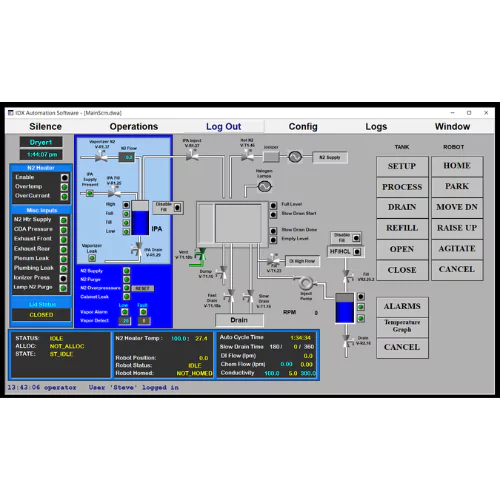

Wafer Drying Utilizing Advanced Hardware, Process Understanding & Software Execution

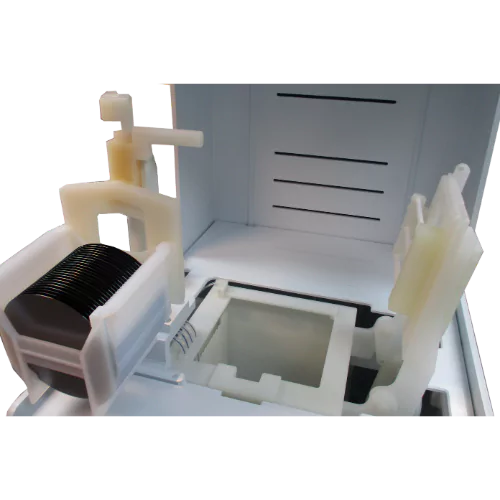

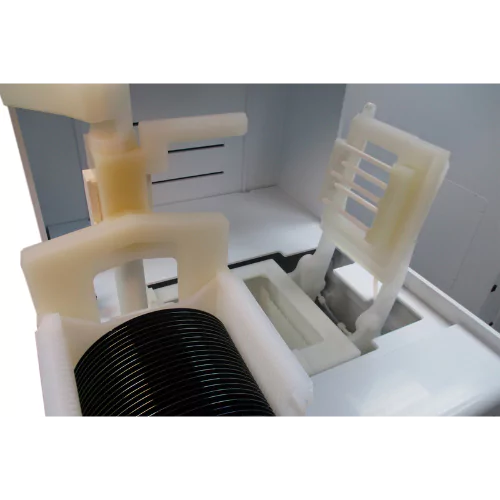

Wafer drying is completed while minimizing contact to production wafers. The Genesis utilizes a proprietary design to ensure the face of the wafer is not contacting the Teflon cassette during the dry cycle.

Features and Benefits:

Improve Yield, Reduce Particles RENA’s integrated Marangoni Dryer provides superior performance by utilizing:

- Manually loaded cassettes or optional automated wafer handling with robot

- Teflon cassettes

- Substrates are free of watermarks after drying

- Enables chemical cleaning before drying with no air interface

- Will not damage sensitive photo resist layers during dry

- Typical cycle times 7-20 minutes

- Dries phobic or philic surfaces

- Host compatible

- Optional chemical injection

- IPA usage 20ml per dry cycle

- Wafer size solutions for 50mm – 200m

- CE marked

Robust, Efficient, Clean & Cost Effective

Varying Dryer Designs Match Varying Needs

- Integrated DI water filtration option

- Optional IPA recirculation for more robust particle performance

- Low cost of ownership

Contact our Experts

We are happy to help our customers find efficient and process-optimized solutions for their wet processing applications.