Asher System Upgrades

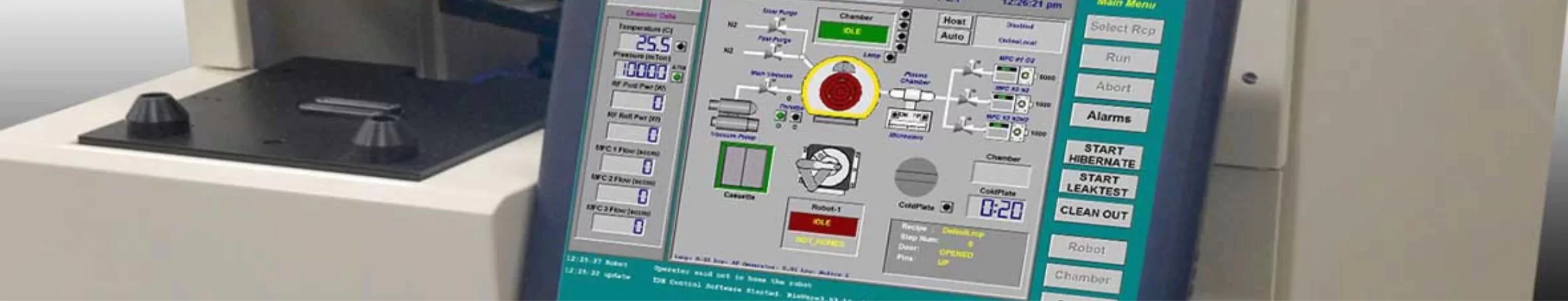

Gasonics L3510 & Matrix 105e Asher Systems Remanufacturing Services & Upgrades

Through our partnership with ESI, the leader in Gasonics L3510 upgrades, RENA is now offering Gasonics L3510 and Matrix 105e remanufacturing services.The newly added benefits, features, and options available through our system upgrades not only extend the life of your equipment, but they improve performance, increase production yield and offer reliable data acquisition to further improve your processing solution. With RENA’s proprietary IDX Flexware Control software the advanced features in data acquisition and process monitoring are unmatched in the industry.

Features and Benefits:

Remanufacturing Specifications:

Test & Qualification

- Configured to customer specification

- Demonstrated at ESI prior to ship

- Full Process 1000 wafers using plasma without error

- No wafer radiation damage during the test

Process and Control Enhancements

- Software version 7.50

- New Pentium® SBC CPU Card

- LCD display and new keypad

- Single cassette processing

- True Downstream Microwave plasma processing

- Automatic photoemission end-point detection

- Calibrated Microwave systemCalibrated Pressure system

- Calibrated Temperature Control system

Advanced Process Control System

- Upgrade your Gasonics L3510 to our advanced ESI e3511 in one day

- Plug and Play plugs directly into the L3510 wiring harness

- IDX Flexware software

- Embedded PC and I/O System

- 17” touchscreen

Electrical Improvements

- New Wiring harness

- New Heated platen, Platen over-temp protection system available as an upgrade

- Wafer cooling station with touch wafer sensor works with glass, GaS etc.

- Lamp assembly with new reflector and bulb with the solid state controller

- New UV igniter bulb and power supply

- Advanced DC Power supplies and A/C distribution with all SSR’s

- New Gerling GL139 1.2kw microwave generator, Mititoyo 3 stub tuner, waveguide, and 6 pole mw applicator

- Latest model I/O PCB and Pressure/EOP PCBs

- MKS ISO valve, new ATM sensor, and new MKS baratron

Mechanical Improvements

- System Hardware compatible with 75-200mm wafers

- Advanced Hine Hatm-5 pick and place robot

- Pneumatics Adjusting block for door and lifter puts all speed adjustments in one place where they are easy to get at.

- UV igniter power supply relocated to the top of the gas box for easy access

- KalRez® high temp O-rings for better resistance to plasma and UV

Plumbing and Pneumatics

- New MKS throttle valve

- Three gas inputs with customer specified MFC’s (typically 4L O2, 2L N2 and 500cc O2)

- New Gas box, Solenoid valves, air cylinders, Tubing

About ESI

ESI has been in business since 1986 with a focus on serving the semiconductor industry. From consulting fabs in Europe on device yield improvement to refurbishing AMAT and LAM tools for customers. ESI has broad experience with plasma Ashing and Etch tools. Offering services and technical support in Semiconductor, MEMS, Biomedical, Nanotechnology & LED industries. We have become the industry leader in remanufactured Gasonics L3510 and Matrix 105e Asher Systems.

Contact our Experts

We are happy to help our customers find efficient and process-optimized solutions for their wet processing applications.